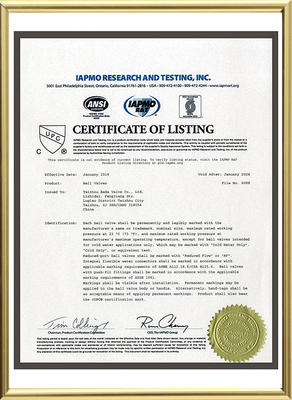

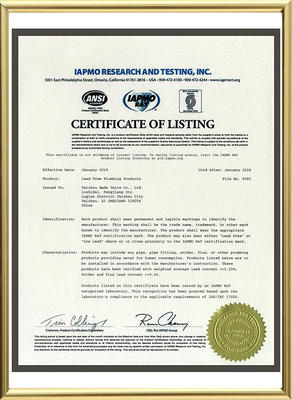

Lead-free brass fittings are used in a variety of applications where water or other liquids are conveyed, such as plumbing, heating, and cooling systems. These fittings are designed to replace traditional

brass fittings that contain lead, which can be harmful to human health and the environment.

Some specific applications where lead-free brass fittings are commonly used include:

Potable water systems: Lead-free brass fittings are ideal for use in systems that carry drinking water, such as pipes, valves, faucets, and fixtures.

Heating and cooling systems: Lead-free brass fittings are also used in heating and cooling systems, such as radiators, boilers, and heat exchangers.

Industrial applications: Lead-free brass fittings are used in a variety of industrial applications, such as chemical processing, oil and gas production, and food processing.

Marine applications: Lead-free brass fittings are commonly used in marine applications, such as shipbuilding and offshore oil and gas platforms.

Lead-free brass fittings are a safe and reliable alternative to traditional brass fittings that contain lead, making them suitable for use in a wide range of applications.

Press Fit Brass Elbow Lifespan

The lifespan of a press-fit brass elbow depends on various factors, such as the quality of the elbow, the installation process, the environmental conditions, and the type of fluid being conveyed. In general, press fit brass elbows are durable and long-lasting, with a lifespan of 20 to 30 years or more.

Here are some factors that can affect the lifespan of a press-fit brass elbow:

Quality of the elbow: The quality of the brass used to manufacture the elbow and the manufacturing process can have a significant impact on the lifespan of the elbow. High-quality brass and precise manufacturing techniques can produce an elbow that is more durable and longer-lasting.

Installation process: The installation process is critical for ensuring the longevity of a press-fit brass elbow. Improper installation can cause damage to the elbow or create leaks that can shorten its lifespan.

Environmental conditions: The environment in which the press fit brass elbow is installed can affect its lifespan. Exposure to extreme temperatures, corrosive substances, or high levels of humidity can cause the elbow to degrade more quickly.

Type of fluid: The type of fluid being conveyed through the

press fit brass elbow can also affect its lifespan. Some fluids, such as acidic or corrosive liquids, can cause the brass to degrade more quickly, shortening the lifespan of the elbow.

Press fit brass elbows are a type of pipe fitting used in plumbing and HVAC systems that are designed to be connected using a press fitting method. Press fit fittings are used to create reliable and leak-free connections in copper, stainless steel, or carbon steel pipes without the need for soldering or other traditional joining methods. A press fit brass elbow typically has the following features:

Material: Press fit brass elbows are made from high-quality brass, which is a durable and corrosion-resistant material suitable for a wide range of applications.

Elbow shape: Press fit brass elbows are typically available in 90-degree and 45-degree angles, allowing for changes in direction in a piping system.

Press fitting connection: Press fit brass elbows have specially designed ends that are compatible with press fitting tools, such as press jaws or press machines. The press fitting connection involves inserting the pipe end into the fitting and using a press tool to compress the fitting onto the pipe, creating a secure and leak-free connection.

O-ring or sealing element: Press fit brass elbows may have an O-ring or other sealing element inside the fitting to ensure a reliable and leak-free connection. The sealing element helps to create a watertight seal between the fitting and the pipe, preventing leaks or seepage.

Size range: Press fit brass elbows are available in various sizes to accommodate different pipe diameters and system requirements.

2025/06/24

2025/06/24 2025/06/20

2025/06/20 2025/06/13

2025/06/13 +86-576-82686004

+86-576-82686004

allen@badavalve.com / daisy@badavalve.com

allen@badavalve.com / daisy@badavalve.com

EN

EN

Español

Español