Production of CC499K Press Fit Bronze Elbow

CC499K is a specific grade of bronze alloy that is commonly used for press fit plumbing fittings, including elbows. The production process of CC499K press fit bronze elbows typically involves the following steps:

Material preparation: The first step in the production of

CC499K press fit bronze elbows is to prepare the raw materials. CC499K is a copper-based alloy that typically contains copper (Cu), tin (Sn), and other elements in specific proportions. The raw materials are carefully measured and mixed to achieve the desired composition of CC499K bronze alloy.

Melting: The mixed raw materials are then melted in a furnace or other suitable equipment to form a molten bronze alloy. The melting process requires precise temperature control to ensure that the alloy reaches the correct melting point and is homogenized to achieve a uniform composition.

Casting: Once the bronze alloy is molten, it is poured into a mold to form the shape of the press fit bronze elbow. The mold is typically made of a heat-resistant material, such as steel, and is designed to create the desired shape and dimensions of the elbow.

Cooling and solidification: After casting, the molten bronze alloy in the mold cools and solidifies, taking on the shape of the press fit bronze elbow. The cooling process is carefully controlled to ensure that the bronze solidifies evenly and forms a solid and homogeneous structure.

Machining: Once the bronze elbow has solidified, it is removed from the mold and undergoes various machining processes to achieve the desired dimensions, surface finish, and tolerances. Machining processes may include cutting, drilling, threading, and other techniques to shape and refine the bronze elbow according to the design specifications.

Press fitting preparation: After machining, the press fit bronze elbow may undergo additional processes to prepare it for the press fitting installation. This may include cleaning, deburring, and polishing the surfaces that will come into contact with other pipes or fittings to ensure smooth and secure connections.

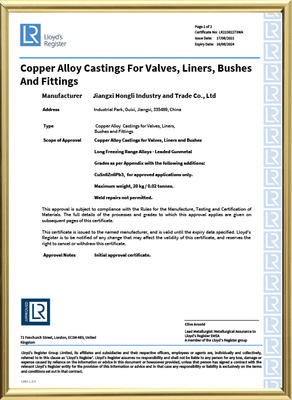

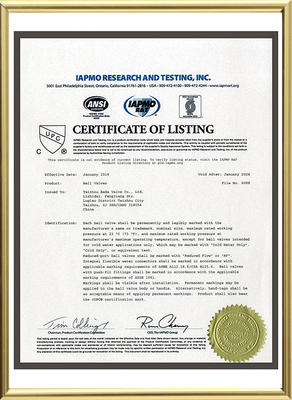

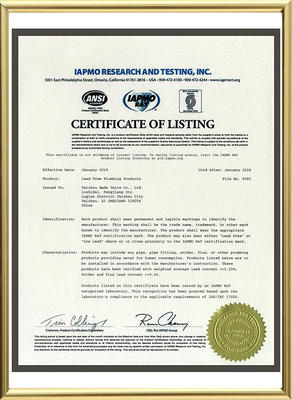

Quality control: Throughout the production process, quality control measures are implemented to ensure that the CC499K

press fit bronze elbows meet the required specifications and standards. This may involve testing the chemical composition, mechanical properties, and other characteristics of the bronze alloy, as well as inspecting the finished elbows for any defects or imperfections.

Packaging and shipment: Once the CC499K press fit bronze elbows have passed the quality control checks, they are typically packaged and prepared for shipment to customers or distribution centers. Packaging may include protective measures to prevent damage during transportation and storage.

2024/07/26

2024/07/26 2024/07/19

2024/07/19 2024/07/12

2024/07/12 +86-576-82686004

+86-576-82686004

allen@badavalve.com / daisy@badavalve.com

allen@badavalve.com / daisy@badavalve.com

EN

EN

Español

Español